News

Recommended Products

Contact Us

Contact Person: Cindy Zhu

TEL:+86 13418453374

Why is CNC machining the best process for aluminum alloy shell processing?

Why is CNC machining the best process for aluminum alloy shell processing?

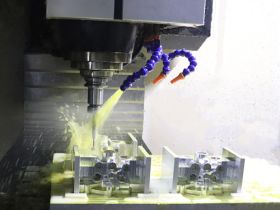

Aluminum products have become one of the most popular profiles at the moment, which has a lot to do with their own materials. Aluminum products are one of the most prominent advantages due to their light weight and delicate appearance. At present, aluminum products are more and more widely used in industry and daily life. Especially in the current era, science and technology are becoming more and more advanced, the society is constantly progressing, and people's requirements for product diversification are getting higher and higher. Therefore, the better the process of aluminum products, the more people will love them, the greater the market demand, the higher the production efficiency, and CNC machining is currently one of the best processing methods for aluminum alloy shell products.

In order to meet people's requirements for diversification and high quality of aluminum alloy shell products, it is necessary to master the process technology in the processing process. Based on years of experience in Shenzhen's CNC machine tool manufacturing industry, the machining skills for processing aluminum alloy shells are summarized. Numerical control processing technology requires that the control system can move and process programs with control codes or other symbolic instructions, and the blanks are processed into semi-finished products with tools. Numerical control cutting is a more reasonable cutting processing method, and it is also a common technology for precision processing of aluminum alloys. The aluminum laser engraving machine adopts multi-cut processing methods, and uses spiral cutting interpolation, trimming processing and other methods. In this way, a small number of holes can be machined with the least pair of tools. Ball end mills and spiral interpolation are used to continuously process tapered holes; ball end mills and spiral interpolation drills can be used for boring and chamfering; hole finishing and precision parts processing are used for thread processing The end mill can be used to process various threaded holes with spiral interpolation. If high-efficiency precision aluminum alloy parts are used to machine high-precision holes of any size, the tool insertion function can be used. Especially in high-speed milling, the load on each tooth is relatively small. The tool uses aluminum laser deep engraving technology. Therefore, the same cemented carbide end mill can be used for high-speed and high-precision hole processing of various materials . For CNC machining of aluminum shells, the machining process should be mastered. The appropriate cutting speed can be selected according to factors such as the processed material, hardness, cutting state, material type, cutting depth, etc. The above conditions are necessary to effectively reduce mechanical wear. Choose suitable fixtures, the parts must fully meet the requirements of the machine to reduce unnecessary positioning errors, and it is best to use special fixtures.

Develop a reasonable processing route and make the processing route as short as possible to reduce the wear of the machine. CNC machining is the best process for aluminum alloy shell processing. It is not accidental. Huazheng Precision has accumulated many years of CNC machining experience for aluminum alloy shells and summed up a whole unique processing experience and technology. Through the actual processing and production process, the use of These mature CNC machining experiences have greatly improved the quality of CNC machining of aluminum shells. Shenzhen industrial model board provides you with hand model, 3D printing, CNC machining, hardware parts processing and other material processing, taking the route of customized processing of non-standard parts, and processing the parts they need for more customers. Only need to provide 2D and 3D drawings of the processed parts, and specific processing requirements, Huazheng Precision can process according to the drawings and give customers a specific part. Because Huazheng Precision can provide customers with one-stop service, from order to delivery, all kinds of processes can be satisfied.

Prev: Shenzhen Huazheng Precision Technology Co., Ltd. CNC Operation Rules and Regulations

Next: Process cost control of CNC machining

Back