News

Recommended Products

Contact Us

Contact Person: Cindy Zhu

TEL:+86 13418453374

According to the characteristics of aluminum profiles, how to better CNC process?

According to the characteristics of aluminum profiles, how to better CNC process?

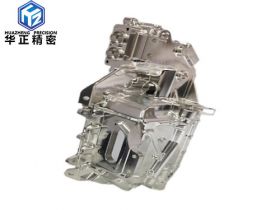

How to achieve the ultimate in aluminum alloy CNC machining? Because aluminum profiles are different from other metals, the texture of aluminum is lighter and softer. In order to meet our diverse and high-quality requirements for aluminum shell products, continuous improvement must be made during processing. According to Huazheng Precision's many years of work experience in aluminum alloy CNC machining, the processing methods that should be considered are summarized.

The precision parts and products of aluminum alloy profiles are favored by everyone because of their lightness, beauty, and other characteristics. They are more and more common in industrial production and daily life. In recent years, with the development of science and technology and the development of the times The market demand for chemical products continued to increase. Therefore, the better the CNC machining process of aluminum alloy, the more warmly welcomed by people, the greater the market prospect and the higher the profit. One of the best processing methods for aluminum alloy products when CNC machine tools are processed.

When the technical requirements of CNC machining of aluminum alloys are required, the automatic control system can be logically set in a specific program flow with control codes or other markings, and the codes are compiled and decoded by the electronic computer for the movement and processing of the CNC lathe. The blank is drilled into semi-finished products, etc.

CNC lathe cutting is a precision drilling process for aluminum alloys, and a more effective drilling method is also a relatively common drilling method. This product uses an alloy milling cutter with multi-directional drilling, helical drilling tool radius compensation and contour drilling tool radius compensation, and it uses some special tools to complete small holes. The ball cage alloy milling cutter used in the application of the helical differential compensation method can be used for continuous processing of tapered holes. The ball cage turning tool and the helical cutter radius compensation drill can be used for boring and chamfering and fillet machining. Precision parts machining, alloy milling cutters and helical interpolation can be used to machine a variety of threaded holes.

For internal and external holes of random specifications, if high-efficiency aluminum alloy precision parts can be processed, numerical control can be applied.

Prev: What are the key points in the CNC operation process?

Next: What are the requirements for materials for ultra-precision parts processing?

Back